Comprehensive Guide to Die Casting Injection Molding: Revolutionizing Metal Fabrication

In the dynamic world of manufacturing, metal fabrication continues to evolve with innovative techniques that enhance efficiency, precision, and durability. Among these techniques, die casting injection molding stands out as a cornerstone process for producing complex, high-quality metal components at scale. At DeepMould.net, a leading metal fabricator specializing in this advanced method, we recognize the profound importance of understanding every facet of die casting injection molding to help our clients achieve optimal results.

Understanding Die Casting Injection Molding: The Fundamentals

Die casting injection molding is a highly automated manufacturing process that involves forcing molten metal into a steel mold—called a die—under high pressure. Once cooled and solidified, the die is opened to reveal intricately detailed metal parts that meet rigorous specifications. This process combines the advantages of injection molding—famous in plastics processing—with metalworking, creating a versatile and highly efficient method of producing complex components.

Core Components of the Process

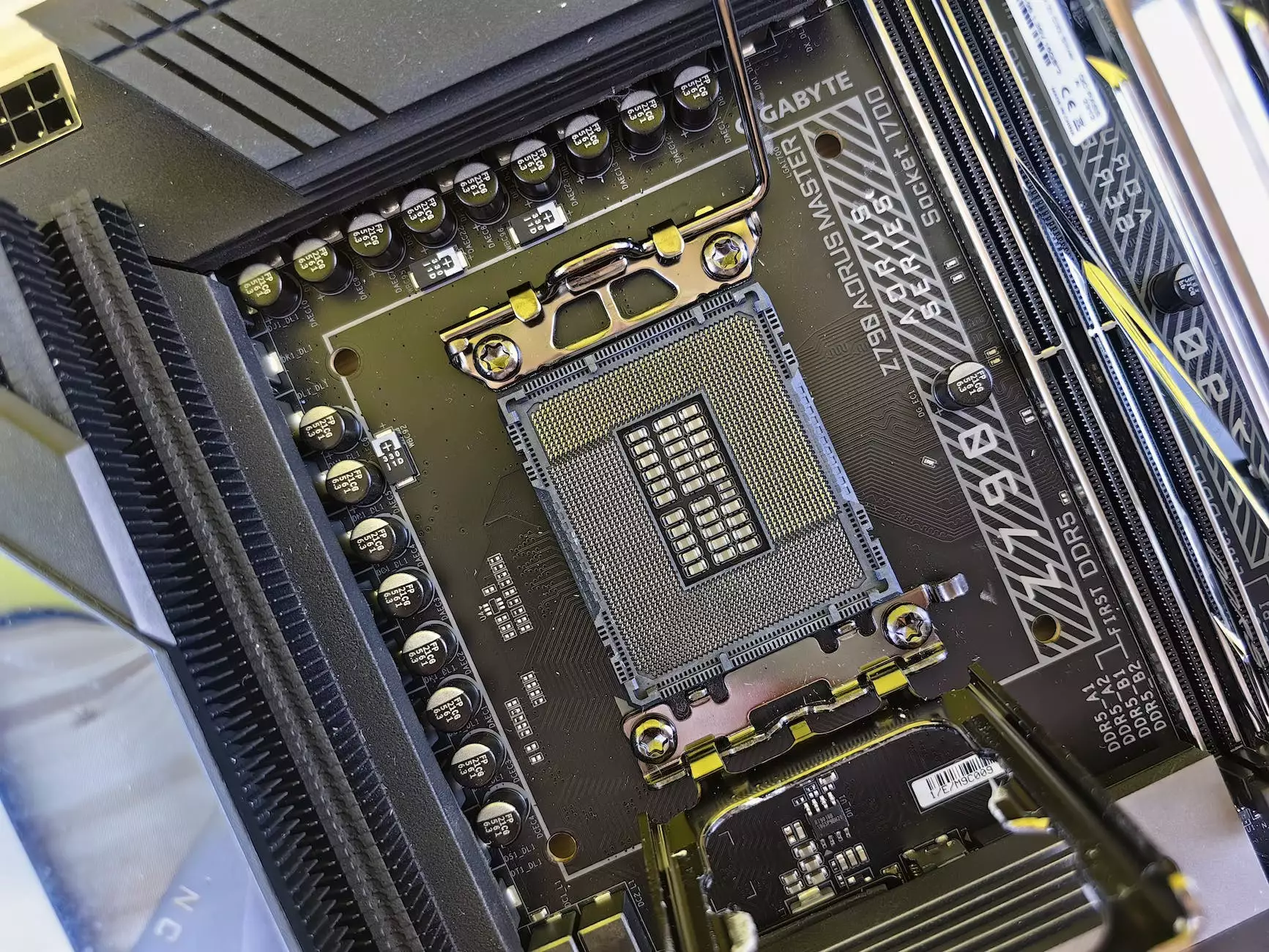

- Die: A precisely machined steel mold that shapes the molten metal.

- Injection System: Pumps and pistons that inject molten metal into the die at high pressure.

- Clamping System: Holds the die halves together during injection and cooling.

- Molten Metal: Typically aluminum, zinc, magnesium, or other non-ferrous metals, heated to a liquid state.

- Ejection System: Mechanisms that release the solidified component from the die.

The Advantages of Die Casting Injection Molding for Metal Fabrication

Embracing die casting injection molding offers numerous benefits for manufacturers seeking precision, volume, and cost-effectiveness. These include:

- High Dimensional Accuracy: Produces parts with tight tolerances, reducing the need for post-processing.

- Complex Shape Formation: Capable of creating intricate geometries that are difficult with traditional machining.

- Smooth Surface Finish: Results in parts with excellent surface quality, often eliminating additional finishing steps.

- High Production Rates: Enables rapid completion of large batches, ideal for mass production.

- Material Efficiency: Minimal waste due to precise metal injection and recycling of scrap material.

- Enhanced Mechanical Properties: Produces parts with excellent strength-to-weight ratios, corrosion resistance, and durability.

Typical Applications and Industries Benefiting from Die Casting Injection Molding

The versatility of die casting injection molding makes it suitable across a broad spectrum of industries, including:

- Automotive: Engine components, transmission housings, and structural parts.

- Aerospace: High-precision structural and decorative components.

- Electronics: Housings, connectors, and intricate small parts requiring detailed features.

- Consumer Goods: Durable, well-finished products such as hardware and appliances.

- Medical Equipment: Components requiring biocompatibility and precision.

Choosing the Right Metal for Die Casting Injection Molding

Selecting the appropriate alloy is crucial to achieving the desired properties, cost-efficiency, and manufacturability. Common metals used include:

- Aluminum Alloys: Lightweight, corrosion-resistant, excellent thermal and electrical conductivity.

- Zinc Alloys: Easier to cast, good strength, and superior surface finish.

- Magnesium Alloys: Very lightweight, suitable for high-performance applications.

- Nickel and Copper Alloys: For applications requiring exceptional corrosion resistance or unique thermal properties.

The Manufacturing Process: Step-by-Step

1. Design and Prototyping

Every successful die casting project begins with meticulous design engineering. CAD software is used to create detailed models, considering factors like wall thickness, draft angles, and placement of ejector pins. Rapid prototyping allows for testing form, fit, and function before full-scale production.

2. Die Preparation

The steel dies are machined and polished with high precision. Multiple cavity dies can produce numerous parts simultaneously, further enhancing efficiency for large batches.

3. Melting and Injection

Metal is heated in a furnace until molten, then injected into the die cavity under high pressure, typically ranging from 10 to 150 MPa. The high pressure ensures the molten metal fills all intricate details of the die.

4. Cooling and Solidification

After injection, the metal cools and solidifies within the die. Cooling time depends on alloy type, component thickness, and die design but is optimized for rapid cycle times.

5. Ejection and Finishing

Once cooled, the die opens, and the part is ejected. Additional finishing processes, such as trimming, machining, or surface coating, are often performed to meet exact specifications.

Innovation and Future Trends in Die Casting Injection Molding

As technology advances, die casting injection molding continues to evolve with innovations like:

- Automation and Robotics: Increasing speed and consistency.

- Computer-Aided Manufacturing (CAM): Enhancing die design accuracy and process optimization.

- High-Pressure Die Casting: Allowing for even thinner walls and lighter components.

- Material Advancements: Development of new alloys with superior strength, corrosion resistance, and ease of casting.

- Environmental Sustainability: Focus on recyclable materials and waste minimization.

Why Partner With DeepMould.net for Your Metal Fabrication Needs?

At DeepMould.net, we leverage extensive industry experience, cutting-edge technology, and a dedicated team of metal fabricators to provide exceptional die casting injection molding solutions tailored to your specific requirements. Our commitment to quality, precision, and timely delivery makes us your ideal partner in manufacturing complex metal parts for diverse applications.

Whether you are seeking small batch prototypes or large-scale production runs, our state-of-the-art facilities and expert engineering support will ensure your project exceeds expectations.

Conclusion: Elevate Your Manufacturing with Our Expertise

The landscape of metal fabrication is continually shifting towards more advanced, efficient, and sustainable methods. Die casting injection molding stands at the forefront of these innovations, offering unmatched capabilities in producing high-quality, intricate, and durable metal components. By choosing a trusted partner like DeepMould.net, you access comprehensive expertise, precise craftsmanship, and a commitment to excellence that will help elevate your manufacturing processes and product offerings.

Investing in die casting injection molding today ensures your business remains competitive, innovative, and ready to meet the demands of tomorrow’s markets. Contact us to learn more about how our metal fabricators can turn your ideas into reality with precision and efficiency.